Flame resistors / Detonation barriers

Flame resistors (also flame arresters or detonation barrier) are used to prevent flame backdrafts or flashbacks in case of ignitibable gas, vapour or air mixtures. These are preventive safety devices to protect against flashbacks and/or spreading explosios or deflagrations.

The detonation barriers are made of a ceramic sintered element made of aluminium oxide, which is high-temperature-resistant and break proof and wich is embedded in a detonation-proof housing. The pores of the sintered element offer sufficient space for the gas mixture flowing through to pass the detonation barrier, but prevent a flame backdraft.

As standard our detonation barriers are ATEX approved. They have a body of stainless steel (1.4571) or Hastelloy.

We are gladly prepared to provide you with the relevant 3.1 certificate of the material supplier. Accessories for mounting the flame arrestors is also available from us.

Detonation barrier F.4.7000.20IIC (Hastelloy) EX II G II C

This detonation barrier (flame resistor, deflagration barrier) has a ceramic sinter body with a passage gap of 80µm and a corpus made of Hastelloy. For mounting the detonations barrier has got an external thread with M30x1,5 and gas connections with a G1/4 internal thread. Please take care of the maximum operation pressure of 3bar and the maximum operation temperature of 200°C. The detonation barrier is 83.5mm long, diameter is 32mm.

Detonation barrier

Detonation barrier F.4.7000.40-IIC (1.4571)

Ex II G II C

IBE x 400 ATEX 2058x

This detonation barrier (flame resistor, deflagration barrier) has a ceramic sinter body with a gas permeable gap of 80µm and a housing of stainless steel 1.4571.

As the construction is nearly identical with the Hastelloy type, the external thread for mounting is M30x1,5 and gas connections are with a G1/4 internal thread. Please take care of the maximum operation pressure of 3bar and the maximum operation temperature of 200°C.

The detonation barrier is 83.5mm long, diameter is 32mm.

Sizes are the same as the Hastelloy type.

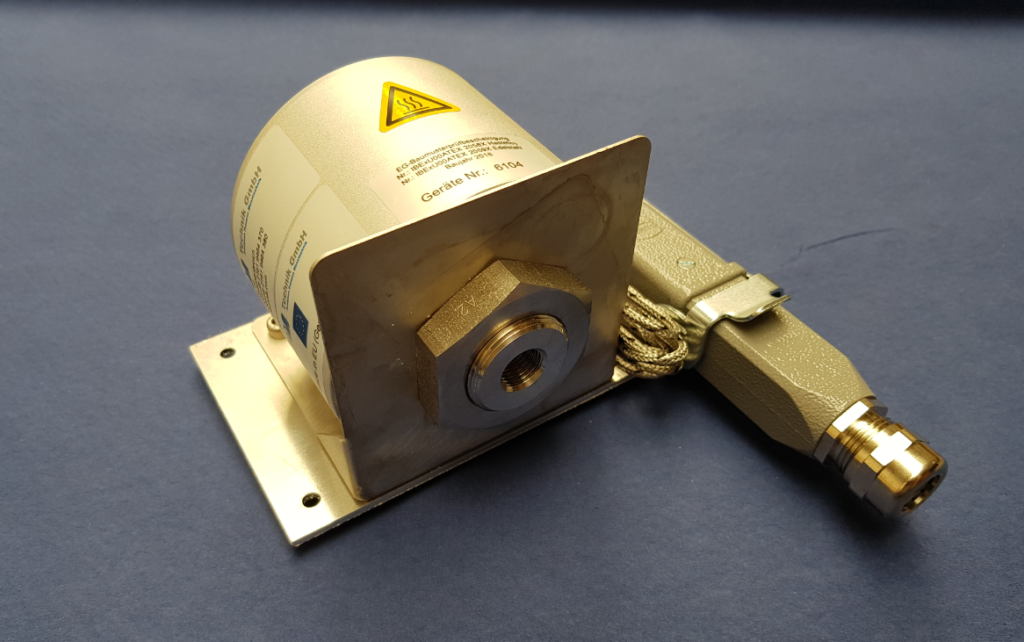

Detonation barrier heated (Hastelloy or1.4571)

The detonation barrier (flame arrestors, flame resistors) F.4.7000.20-IIC and F.4.7000.40-IIC are also available as heated versions. The detonation barriers can be ordered as ATEX-certified version.

The heated versions of the flame arrestors (also called safety modules, deflagration barriers) are used when with humid sample gas condensate arises, which may lead to danger, blocking of the sintered body or other defects. This happens if the dewpoint of the extracted gas is not reached.

The heasted detonation barrier consists of a detonation fuse, the heating, the casing, mounting bracket and plug connection, as well as an external heat control. The distance between control and heating may be up to 2 meters.

Detonation barrier F.4.2000.20-IIC (Hastelloy)

This type of detonation barrier (flame arrestor, flame resistor, deflagration barrier) has a body made of Hastelloy and inside a ceramic sinter element.

The detonation barrier belongs to explosion group IIB. It is connected via 2″ gas connections, any installation position can be selected. On request it is possible to offer flange-mounted versions. Length of the flame resistors is 140mm, diameter is 80mm.

Do not exceed the maxiumum operation temperature of 80°C and the maximum operation pressure of 3bar.

Detonation barrier F.4.2000.40-IIC (1.4571)

This type of detonation barrier (flame resistors, deflagration barrier) is the stainless steel version made from 1.4571. Inside the detonation barrier there is a ceramic sinter element.

It is connected via 2″ gas connections, any installation position can be selected. Length of the flame resistors is 140mm, diameter is 80mm.

Do not exceed the maxiumum operation temperature of 80°C and the maximum operation pressure of 3bar.