Transmitter for different gases

Gas-TR

The gas transmitters Gas-TR work according to the principle of thermal conductivity (WLD/TCD). They enable a continuous analysis of the concentration of various gas mixture components in industrial and laboratory applications. Also they are applied for mixing and production of spcial gases. The transmitters can be equipped with touch display (optional) ,WLAN and with various connection options.

The gas transmitters are suitable for gas analysis in corrosive and non-corrosive applications.

The principle of thermal conductivity (WLD/TCD) is based on the dependance of the temperature of a heated resistance wire from the thermal conductivity of the gas which surrounds this wire.

The measuring cell has two opposite measuring cuvettes (Wheatstone bridge). One cuvette is surrounded by the sample gas and the other one forms the reference. The cuvette, which is surrounded by the sample gas, changes its electrical resistance equivalent to the concentration of the gas to be analyzed. This leads to a change in the output voltage.

Gas transmitter Gas-TR - Information

Gas-TRT – TCD transmitter with touch display and gas connection via 6mm pipe fittings

Gas-TRD – TCD transmitter with touch display and process flange KF-16

Gas-TRL – TCD-Transmitter without display and gas connection via 6mm pipe fittings

Gas-TRB – TCD – Transmitter without display and process flange KF-16

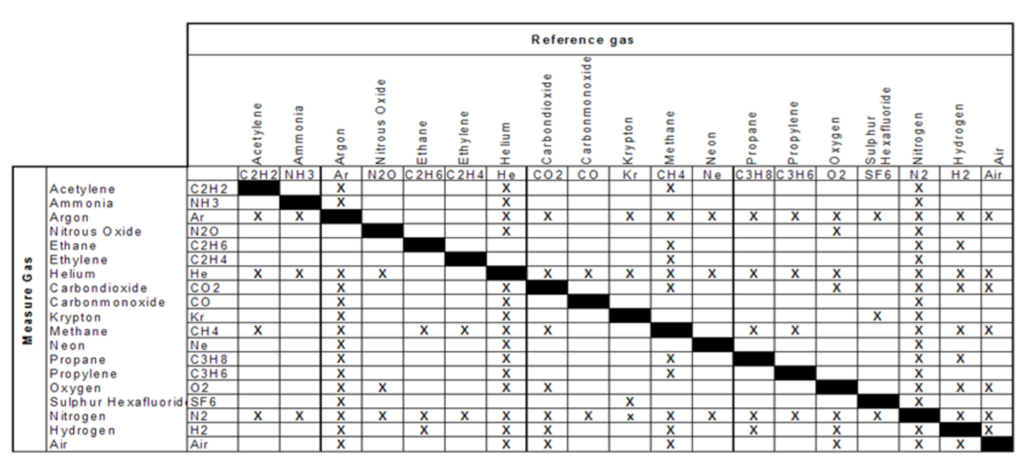

The gas transmitter Gas-TR has been designed for analysis of different gas concentrations. In order being able to analyse specific sample gases with the thermal conductivity transmitter (TCD) precisely, the thermal conductivity of the sample gas must differ significantly from that of the background gas. The gas analyzer Gas-TR can be applied in the following gas mixtures, amongst others:

Measuring data:

largest measuring range: 0 … 100 % (depending on application)

lowest measuring range: 0 … 1000 Vol.ppm H2

Sample gas flow: 5 … 100 l/h

max. operation pressure < 15 bar (in a vacuum error correction required from approx. 15 mBar abs.

max. gas temperature 50°C

pressure drop over the sensor 0,1 mBar (10 mm WS) at 40 l/h

Explosion protection possible on request

General data:

Connections: KF-16, 6mm clamping ring, others on request

Dimensions: 200 x 100 x 150 mm

Protection class: IP54 (vgl. DIN 40 050)

Weight: 2 kgs approx

Operation temperature +5 … + 55 °C

Storage temperature: -20 … + 60°C at 0 … 95 % rel. humidity

User Interface Touch-Display (only with Gas-TRT)

(not with version Gas-TRB)

Elektroncal data:

Voltage supply: 24 V / DC

Power consumption: < 30 VA

Data output:

Analogue output 0 … 20 mA or 4 … 20 mA active, galvanically isolated

Others: WLAN optional

Gas transmitter Gas-TR - applications and benefits

Typical applications

- Aluminium industry

- Analysis of gas storage

- Gas manufacture

- Special gases

- Inert glove boxes

- Laboratories

- Semiconductor industry

- Bond furnaces

- Pharmaceutical industry

- Chemical industry

The benefits at a glance

- For different sample gases

- Can be positioned directly in the process, InSitu measurement

- Excellent reproducibility of measuring values

- Maintenance and calibration in Germany

- Small design

- Touch display with tilt detection

- Good readability

- User-friendly

- WLAN on request

Datenblatt